När det gäller automatisering på fabriks- eller lagergolvet kan det göra stor skillnad att ha logistikboxar i exakt rätt storlek och av plast. Vad händer om boxarna inte passar exakt? Eller är en aning för stora eller små? Maskiner kan då fastna, köras långsammare eller till och med gå sönder. Därför är det så viktigt att alla boxar har samma storlek och form. Hos NEXARA förstår vi hur viktigt detta är, eftersom vi gång på gång har sett hur små fel i boxstorlek kan orsaka stora problem i stora automatiserade system. Det handlar inte bara om att se snyggt ut, utan om att kunna arbeta snabbt och effektivt utan att hela produktionslinan hela tiden måste stoppas. När boxarna är enhetliga kan robotar och transportband hantera dem sömlöst, vilket sparar tid och pengar. Men när de inte är det blir det rörigt, och arbetare måste lösa problem som maskinerna inte ens borde ha.

Insikt i automatiseringseffektivitet för plasttransportboxar tack vare dimensionell konsekvens

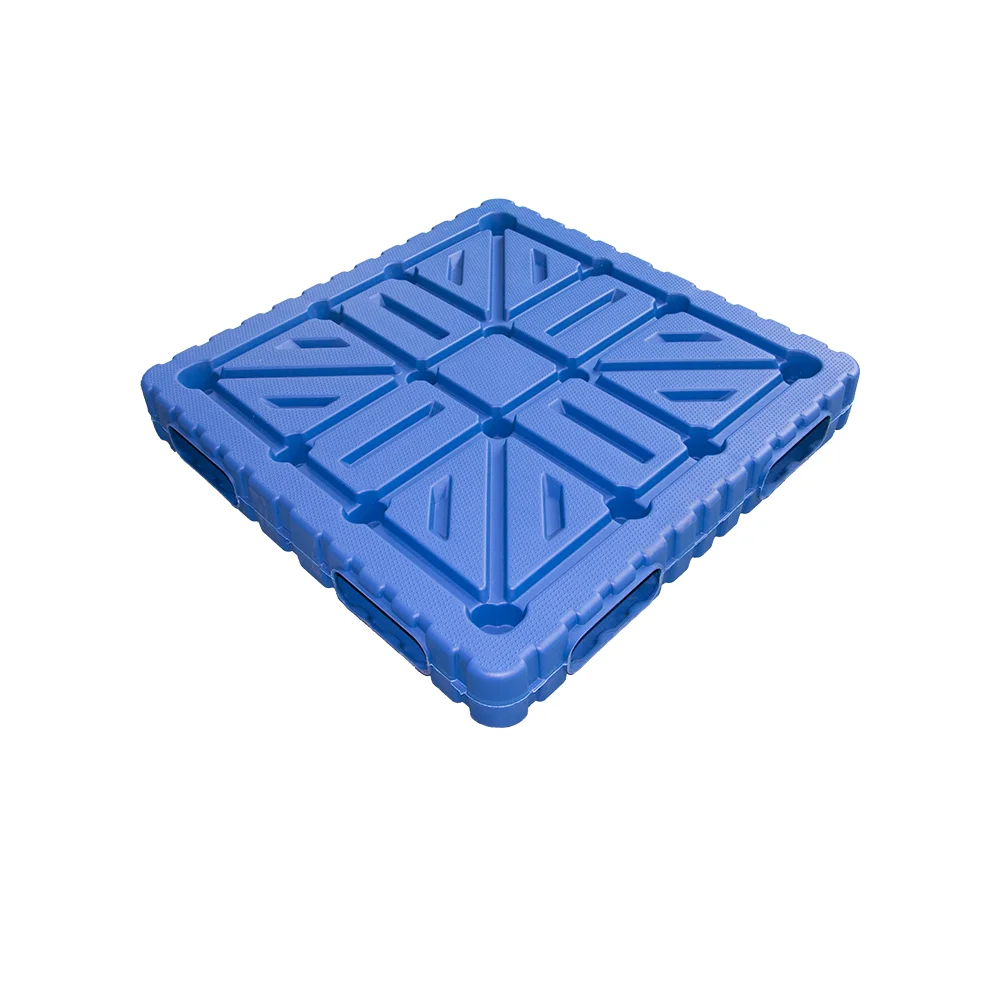

Dimensionellt exakta. Alla lådor är modellerade efter standardiserade europeiska mått, vilket säkerställer att alla produkter kan staplas ovanpå varandra och att den låda du köper idag får ett lock i morgon. Om lådorna är ojämna, även bara lite grand, kan maskiner som sorterar, staplar och flyttar dem störas. Till exempel, om en transportbana är avsedd för lådor exakt 12 tum bred, fungerar den inte lika bra med lådor som är något mindre eller större, till exempel 11,8 tum eller 12,2 tum. Denna lilla variation kan leda till att lådor välter eller fastnar. Hos NEXARA förstår vi att små storleksvariationer kan leda till stopp och förluster. Robotar plockar vanligtvis upp lådor med mekaniska armar eller sugkopp, och om lådan inte har enhetlig storlek kan roboten misslyckas med att gripa tag i den eller tappa den. Det stoppar hela processen tills det är åtgärdat. Det är tidskrävande och dyrt.

Och automatiseringssystem har en inställningsregel för lådstorlekar. Felaktiga kommandon kan skickas av programvaran när lådor inte överensstämmer med dessa storlekar. Detta kan orsaka stopp eller fel. Tänk dig ett förpackningsband där lådor välter bara för att de inte passar i maskinernas utrymmen. Det är frustrerande och farligt. Sådana problem ansåg vi var vanliga inom många anläggningar, och det handlar i slutändan om inkonsekventa lådstorlekar. En enhetlig storlek gör att maskinerna kan fortsätta arbeta utan avbrott. Det innebär färre fel och snabbare förpackning samt säkrare arbetsplatser. Därför fokuserar NEXARA på strikt dimensionskontroll i varje låda vi tillverkar. Vi testar regelbundet för att säkerställa att varje låda matas korrekt in i automatiserade system. En sådan noggrannhet gör stor skillnad i hur effektivt automatisering fungerar. Det handlar inte bara om att tillverka lådor; det handlar också om att göra hela upplevelsen smartare och smidigare.

Var hittar man de bästa plastlogistikboxarna med exakt månadimension?

Att söka efter logistikboxar i plast med specifika dimensioner är inte lika enkelt som man kan tro. Storleksuppgifter är inte alltid något alla tillverkare bryr sig om, och det är just sådana enkla saker som ofta orsakar stora problem för företag som använder automatisering. Men NEXARA är stolta över att kunna erbjuda kunder boxar som följer strikta dimensionalregler. När du köper av oss behöver du inte längre oroa dig för att boxarna ska fastna i din automatiserade linje. Vi tillverkar boxar under kontinuerlig övervakning och på maskiner som håller nära toleranser, vilket innebär att storleken förblir nästan densamma hela tiden. Detta garanterar att dina behov fungerar smidigt utan avbrott.

Till exempel, i ett projekt bytte ett företag till NEXARAs lådor och ökade sin packhastighet eftersom de nya lådorna passade perfekt på deras transportband och robotarmar. De stopp och fallna lådor som tidigare stört dem försvann. Vi kan även erbjuda skräddarsydda storlekar, om din automatisering kräver särskilda lådor. Denna flexibilitet är avgörande, eftersom inte alla system är likadana. Och lådorna från NEXARA är tillverkade av slitstarkt plastmaterial som inte deformeras eller krymper. Detta bidrar till att storlekarna förblir konstanta vid långvarigt bruk. Vissa lådor kan ändra storlek i varmare eller kallare delar, men våra behåller samma form, vilket säkerställer en smidig automationsprocess.

När du letar efter det bästa plastlogistiklåda , är det en bra idé att samarbeta med ett företag som förstår vad du verkligen behöver. NEXARA lyssnar på dina behov och hjälper dig att hitta den bästa lådstorleken som passar dina maskiner. Vi känner till risken med att förlora tid och pengar när lådor inte passar precis rätt. Därför fokuserar vi på att tillverka lådor med perfekta mått och form varje gång. Allvarligt talat, om du vill att din automation ska fungera smidigt, är det nödvändigt att du får lådor med exakta mått – och NEXARA kan hjälpa dig med just det.

Söker dimensional variation hos plastlogistiklådor som stör automation!

När du arbetar med plastlogistiklådor i automatiserade system blir lådornas storlek och form ännu viktigare. På grund av målskillnader har lådorna inte varit helt identiska med sin avsedda form. Dessa små avvikelser kan bli katastrofala i maskiner som flyttar lådorna automatiskt. Hos NEXARA förstår vi att det är absolut nödvändigt att varje enskild låda passar perfekt i maskinerna utan att klämma sig eller orsaka ett fel.

För att upptäcka dessa avvikelser måste du först mäta lådorna noggrant. Genom att använda enkla verktyg som linjaler eller skjutmått kan man kontrollera om lådans längd, bredd, höjd och så vidare är korrekt. Även mindre avvikelser, bara några millimeter, kan få en låda att klämma sig i en transportbana eller inte passa i ett robotarms grepp. Ibland kan lådor verka korrekta för blotta ögat men ändå vara något smalare i mått. Därför är det viktigt med precision vid användning av mätutrustning.

Ett alternativt tillvägagångssätt för att uppnå mångivningsvariation är experimentell provning av lådorna i ett automatiserat system. Om maskinen inte fungerar ordentligt, ofta fastnar eller släpper lådor, kan det bero på att lådorna har felaktig storlek. Arbetare kan iaktta hur lådorna rör sig genom systemet och identifiera eventuella problem. Om vissa lådor orsakar betydligt fler problem än andra, kan det vara möjligt att dessa lådor har olika storlek.

NEXARA är inriktat på tillverkning av högprecisions plastlådor för logistik. Därför tillverkas varje låda med nästan exakt samma mått, vilket gör det enkelt för maskiner i automatiserade system att fungera sömlöst. Maskiner kan plocka, förflytta och stapla lådor utan fel när lådorna är enhetliga. Detta minskar tidsåtgången avsevärt och resulterar i en smidigare arbetsprocess.

Kort sagt, det lönar sig att veta när måtten ändras – granska storleken på plastlådor noggrant och observera hur de fungerar i maskiner. Hos NEXARA ser vi till att våra lådor har exakt samma storlek så att automatiserade system inte stöter på problem. Detta förhindrar förseningar för företag och säkerställer effektiv arbetsgång.

Vad grossistlogistikföretag bör veta om måttliga toleranser i plastlådor

Grossistlogistikföretag är nästan helt beroende av olika typer av plastlådor för lagring och transport av sina produkter. Dessa företag använder ofta maskiner som kan flytta lådor snabbt och säkert. Måttligheter är kritiska inom denna bransch. Måttlig tolerans innebär hur mycket en lådas storlek kan avvika från det faktiska måttet och ändå fungera korrekt. Hos NEXARA förstår vi att om toleranserna är för stora kan maskinerna fungera felaktigt. Om toleranserna är för strama kan förpackning bli kostnadsdrivande eller långsam.

Engrosslagerföretag arbetar med tanke på att det i varje låda kommer att finnas en toleransomgång. Till exempel kan en låda som ska vara 50 centimeter lång tillåtas variera mellan 49,8 och 50,2 centimeter i längd. Detta smala intervall är den acceptabla toleransen. Om någon låda inte ligger inom detta intervall kanske den inte passar ordentligt i maskiner eller hyllor. Att känna till detta gör att företag kan sätta regler för de lådor de köper och använder.

För engroshandelsföretag är det avgörande att samarbeta med leverantörer som NEXARA, som har god kontroll över dessa toleranser. NEXARA använder modern teknik för att tillverka p plastpalllåda med extremt stränga toleranser, ett tekniskt uttryck som innebär att lådorna är mycket nära den exakta storleken som krävs. Detta gör att maskinerna kan hantera lådorna bättre och minskar risken för problem som stopp eller trasiga lådor.

Engrosslagerföretag bör också ofta kontrollera sina lådor. Välproducerade lådor kan tillverkas med goda toleranser, men transport och hantering kan ibland förändra deras form. Regelbunden kontroll förhindrar att lådor av felaktig storlek används. Den upptäcker problematiska maskiner innan de orsakar större problem och gör det möjligt att ta dem ur drift eller reparera dem.

I stark kontrast gäller, om du är ett engroslagerföretag, att dimensionell tolerans är något som du inte kan bortse från om verksamheten ska fungera smidigt. Genom att samarbeta med NEXARA utvecklas plastlådor i perfekt storlek, vilket gör att maskiner fungerar bättre och underlättar hanteringen.

Den roll som dimensionsmässig enhetlighet spelar för att minska driftskostnader i ett program för engrossvinn av plastpallar

För grossistlogistik är det mycket viktigt att alla plastiska logistiklådor har samma storlek varje gång. Detta kallas bevarande av dimensionell giltighet. Med enhetliga lådor kan maskiner och arbetare arbeta snabbare och med färre fel. Hos NEXARA ser vi till att varje enskild plastlåda uppfyller de stränga storleksreglerna så att företag kan spara pengar.

Eftersom lådorna inte har samma storlek kan maskiner stanna eller sakta ner eftersom de måste bearbeta varje låda på olika sätt. Detta förlamar processen och kan till och med skada maskinerna eller göra dem osäkra. Och arbetare kan behöva lägga mer tid på att hantera dessa problem istället för att arbeta med andra viktiga uppgifter. Med enhetliga lådor fungerar maskinerna smidigt, och arbetare kan ägna sin tid åt mer produktiv arbetsinsats.

Dimensionell konsekvens innebär också färre skadade varor. Dåligt sittande lådor klarar sig inte bra på pallar eller hyllor, där de kan välta och krossas. Det kan förstöra innehållet i produkterna. Att ersätta skadade produkter kostar pengar och medför förlorad tid. Håll din produkt säker i en NEXARA tryckt låda, perfekt för både leverans och lagring.

Ett annat sätt som konsekventa lådor sparar pengar är genom att minska spill. Om lådorna inte har rätt storlek kan företag behöva kassera eller återvinna lådor i förväg, vilket kan bli dyrt. Eftersom NEXARA tillverkar lådor enligt exakta specifikationer kan företag ta emot lådor som håller längre och fungerar bättre, istället för att vara tvungna att skicka halvtomma.

Slutligen hjälper lådor som är konsekventa till att företag kan planera bättre. Att veta att varje låda alltid kommer att ha samma storlek är till hjälp vid utformning av lagringsutrymmen och val av utrustning. Denna förhandsplanering sparar pengar genom att undvika överraskningar och onödiga inköp.

tredjedelar kvarstående dimensionella fosfor logistiklåda kan spara kostnader när den kombineras med maskinproduktivitet, varuskydd, avfallsminskning och hjälp till planeringsfrågor. Hos NEXARA fokuserar vi på kvalitet så att grossistlogistikföretag får de bästa lådorna för att driva sina verksamheter smidigt och till en kostnad de kan betala.

Innehållsförteckning

- Insikt i automatiseringseffektivitet för plasttransportboxar tack vare dimensionell konsekvens

- Var hittar man de bästa plastlogistikboxarna med exakt månadimension?

- Söker dimensional variation hos plastlogistiklådor som stör automation!

- Vad grossistlogistikföretag bör veta om måttliga toleranser i plastlådor

- Den roll som dimensionsmässig enhetlighet spelar för att minska driftskostnader i ett program för engrossvinn av plastpallar

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

GA

GA

CY

CY

BE

BE

BN

BN

/images/share.png)