Automated warehouses pledge faster work, with less room for human error. But use the wrong plastic pallets, and things can turn south quickly. Plastic pallets might not appear sexy, but they are essential for keeping everything in order. At NEXARA, we understand that the wrong pallet can mean big problems product damage, machine downtime and worker dissatisfaction. In this article, we discuss why choosing the best plastic pallets isn’t just a common sense decision but also a necessity in any automated warehouse. Without them, your system might just drop the ball before you get off the field.

What Are the most Common Mistakes Behind Automated Warehouse Failures When Using Plastic Pallets Improperly

A lot of firms are already in the world of automation without giving a whole lot of thought to what type pallets they have. This is a big mistake. First, all pallets are not created equally. Cheap pallet pats, or the wrong kind of plastic can crack, bend and wear out sooner. When that happens, automated machines robots or conveyors, for example can no longer grasp and move goods correctly. Think of a robot arm trying to pick up a pallet that’s broken or warped; it won’t function properly. At NEXARA, we’ve encountered warehouses where the wrong pallets led to acute jamming of machines and frequent stoppages. The downtime is costly and time consuming.

Another error is disregarding the size and weight restrictions on pallets. Pallets that are oversized or overweight for your system puts organs on machines. Or they can become blocked or misaligned. At times wood pallets can be replaced with plastic ones, however this is something that you should examine before doing so. But wooden pallets frequently are a poor fit for automated machinery. Our pallets more check out. This prevents errors that result in crashes or damaged goods.

Finally, many forget about safety. Substandard pallets can crack in transit, leading to accidents. Workers could be injured or products might fall and break. By investing in NEXARA plastic pallets you will receive robust, safe platforms engineered for automated handling shock. Passing over the correct pallets is often at the expense of damages, delays and unsafe working conditions. The errors aren’t hard to make, but they are difficult to undo. Select right plastic pallets upfront to keep your automated warehouse on track.

Plastic Pallets and Enhancing Product Quality in Automated Warehouses And Decreasing Downtime

Using NEXARA plastic pallets, you can have much better handling and make machines run longer without interrupting. Smooth surface and strong pallet: Made from plastic. They won’t splinter or deteriorate like wooden pallets. In other words, the goods remain clean and safe throughout storage and shipping. Pallets that don’t contaminate or harm food or electronics, for instance. NEXARA plastic pallets fulfill these requirements ideally. They help products stay fresh and untouched customers like that.

One of the mortal enemies of automated warehouses is downtime. When the machines go down, everything comes to a grinding halt. Plastic pallets are used to minimize this downtime. Robots and conveyors can grab them and move them. There are no surprises such as warped boards or nails that didn’t hold. At NEXARA, our experience shows warehouses that use the right type of plastic pallet have less machine jam and maintenance. The result has the effect of allowing workers to focus on other tasks and getting goods through the system faster.

Also, plastic pallets last longer. They do not absorb moisture or rot, as wood does. This eliminates replacing pallets constantly. The fewer replacements are necessary, the less interruption and cost. Switching to NEXARA plastic pallets in one case saved thousands of dollars a year due to having less pallet failures.

Plastic pallets also improve safety. They are lighter than wood and yet strong, reducing the risk of injuries for workers handling them manually. Safer working conditions are happier workers and fewer accidents that can shut down production.

So, yes plastic pallets are much, much more than just a bin. They keep products safe, make machines perform better and help ensure that the warehouse operates for longer without any issues. The benefits of our system are the legs that our plastic pallets are designed on to help your automated warehouse thrive.

Why It Is Crucial for Wholesale Buyers to Invest in Durable Plastic Pallets For Automated Storage Systems

If you operate an automated warehouse, then choosing the right type of plastic pallet is critical. Durable Plastic Pallets for Wholesale Buyers If you have many products to store and move in a short period of time, then durable plastic pallets are definitely the way to go. Heavy Duty PalletsStrong pallets are resilient and cannot crack or break when carrying heavy loads. That is to say, they safeguard products as they are shuffled around warehouses by machines. They could crack or otherwise be damaged in handling, holding up shipping and adding cost. And durable pallets also last longer, so buyers save money by not having to go through replacement as often. This is a money-saver in the end.

NEXARA knows that WMS autonomous storage systems require pallets that are 100% compatible with customers machines. Our robust plastic pallets are suitable for use in automatic warehouses. They are smooth and perfectly sized, so robots and conveyors can pick them up without a hitch. When conveyor pallets pair perfectly with machines, the entire system moves faster and more smoothly. For wholesale purchasers, that translates to quicker shipping times and happier customers.

Another reason to select only the strongest plastic pallets is safety. In an automated warehouse, machines can shuffle pallets very quickly and in volume. If a pallet breaks, it can lead to accidents or damage other products. Pallets that are resistant are less likely to cause accidents as they remain strong under pressure. NEXARA’s plastic pallets are manufactured with high-performance materials that do not crack nor wear. This helps safeguard the workers, equipment and products.

Lastly, strong plastic pallets make maintaining your warehouse a far simpler process. They're also easy to clean and don't soak up water and dirt like wooden transport pallets can. A clean pallet is less likely to bring pests or mold with it. For wholesale purchasers, this is convenient for keeping orders safe and nice. Selecting NEXARA’s robust plastic pallets is to opt in favor of quality, safety and efficiency for automated storage systems.

What Are the Dangers of Low-Quality Plastic Pallets for Automation Warehouse Use?

Oh, the problems you can have when using cheap industrial pallet racks in an automated warehouse! These risks can clog the warehouse and even bring heavy losses. Weak or poorly made pallets are prone to break or to be crushed when machines try to move them. This can shut the machines down and lead to delays. In an automatized warehouse work system even a slight delay may disturb many orders and lead to dissatisfied customers.

Poor quality pallets can even cause the products to be carried on them to be damaged. And, if a pallet cracks or gives way without alerting nearby workers, products can fall or be crushed. This in turn can result to unusable products and more money spent for replacement. For wholesale purchasers when the products are lost due to poor pallets, not only trust of the customers is shaken but also business is damaged.

Another big risk is safety. Disturbance can mean little in a wave of automation, but machines in automated warehouses move quickly and shattered pallets can lead to accidents. Workers may be injured if they attempt to manage damaged pallets or clean up following a break. Broken pallets can also damage the machines, and the repair or replacement is expensive. These additional expenses can quickly escalate and create significant challenges for warehouse managers.

Low-grade plastic pallets can deteriorate fast as well. Buyers are now forced to buy new pallets more frequently, which adds costs and becomes more work. Conversely, well-constructed pallets last longer and save money over time. They also help to keep the warehouse operating smoothly, as machinery is not forced into frequent stops for repair or cleaning.

With NEXARA you can choose plastic pallets of a high quality with no possible risks. Our pallets are proven to withstand the weight of heavy loads and are compatible with automated systems. Picking NEXARA is the difference between never having issues with your warehouse, while also avoiding all the problems subpar pallets cause.

What are the Best Plastic Pallets for High-Speed Automation Warehouses?

Selecting the right plastic pallets for a high-speed automated warehouse is challenging, but when you know what to look for I done make a difference. The correct pallet must be a good match with the equipment and strong enough to hold heavy loads without buckling. Wholesale buyers should look for a few key features when buying pallets.

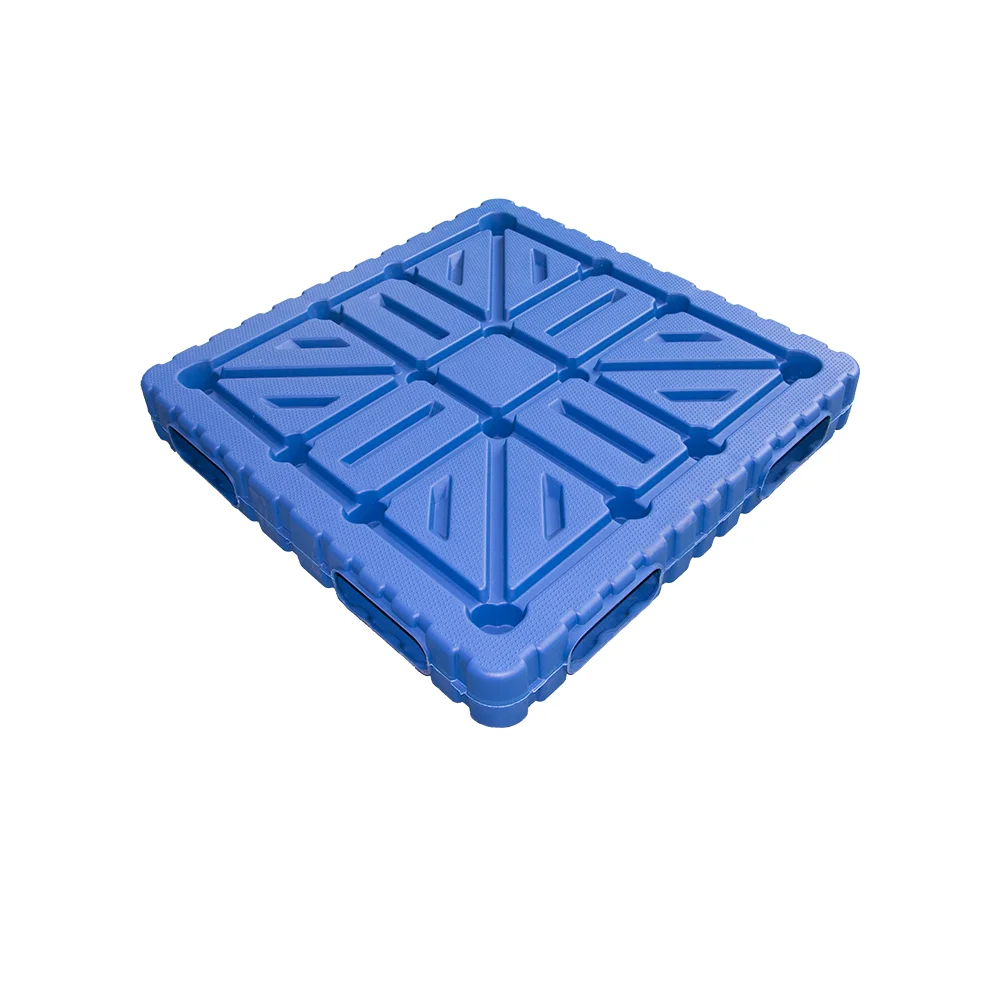

The pallet must, first and foremost, be sturdy plastic. This substance should be crack, impact-and wear-resistant over a certain period of time. NEXARA plastic pallets are designed to be strong and sturdy to withstand the toughest applications. Stronger pallets amount to fewer breaks and less down time in the warehouse.

Secondarily, search for pallets with uniform size and shape. For automated machinery to pick up and move a pallet without error, it has to fit just so. When pallets are uneven or an incorrect size, machines can drop them or malfunction. NEXARA manufactures precisely measured pallets that work seamlessly with automated systems, for quicker warehouse management.

Third is the weight of the foldable plastic crates. Too heavy and the machines may run more slowly or consume too much energy. If it’s too light, the risk is that it won’t be strong enough to support a heavy load. NEXARA’s plastic pallets are designed to be lightweight and heavy-duty, ideal for high-speed environments.

And lastly, it’s nice to go for pallets that are easy to clean and maintain. They have to be clean pallets and they do keep your products safe and you won’t have problems with pests or dirt. NEXARA pallets are easy to clean and keep clean with smooth surfaces that can withstand washing in the fast-paced environment of any warehouse.

Knowing these features and selecting NEXARA plastic pallets, bulk buyers can ensure their automated warehouses operate well and continue to remain cost-effective. The right pallets help you run machines better, protect products and ultimately save money over time.

Table of Contents

- What Are the most Common Mistakes Behind Automated Warehouse Failures When Using Plastic Pallets Improperly

- Why It Is Crucial for Wholesale Buyers to Invest in Durable Plastic Pallets For Automated Storage Systems

- What Are the Dangers of Low-Quality Plastic Pallets for Automation Warehouse Use?

- What are the Best Plastic Pallets for High-Speed Automation Warehouses?

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

GA

GA

CY

CY

BE

BE

BN

BN

/images/share.png)