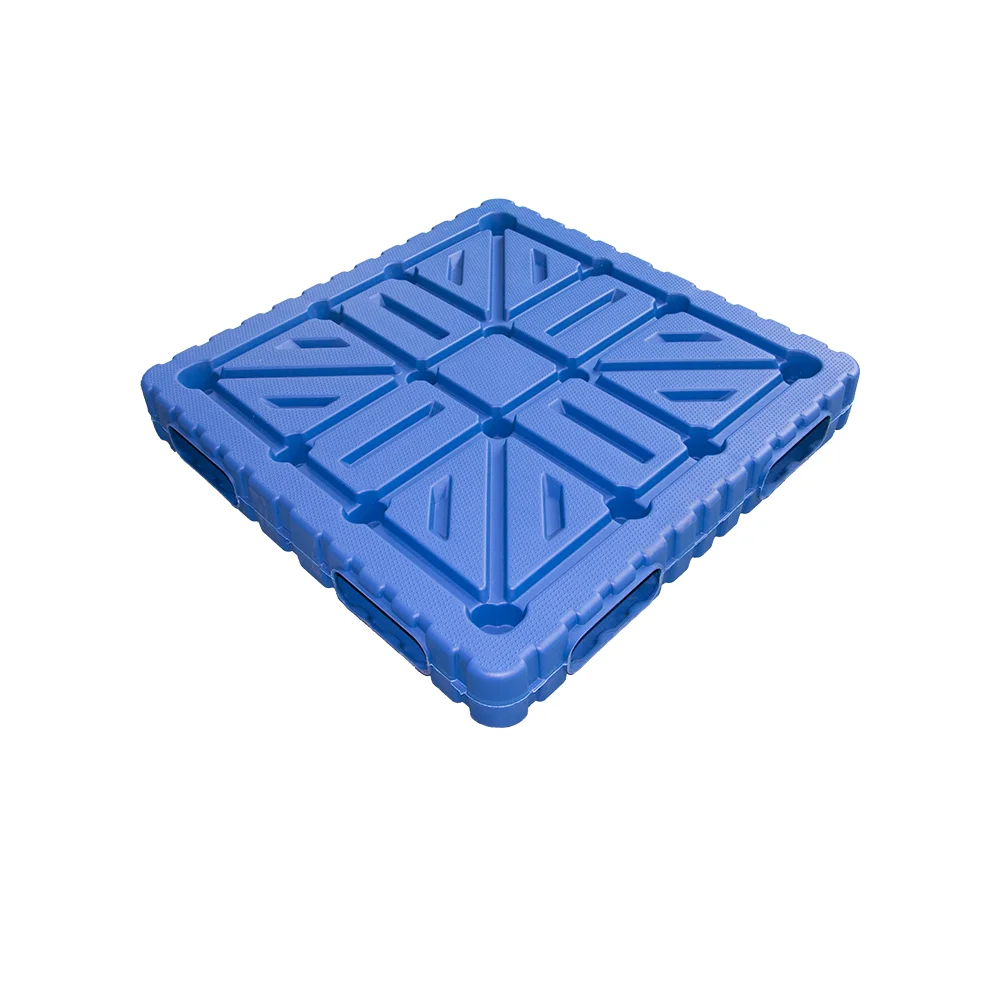

Les companyies automobilístiques necessiten que els components es moguin i emmagatzemin de manera segura en caixes especials. Són caixes per a petites femelles i cargols i peces grans del cotxe que no es trenquen ni desapareixen. Aquí a NEXARA, produïm la caixa logística de plàstic que millor satisfà aquestes necessitats. Les nostres caixes es poden personalitzar per adaptar-se a cada tipus de peça d'automòbil, a diferència de les caixes típiques. Això pot ajudar els treballadors a localitzar les peces més ràpidament i fa que el taller estigui més endreçat. Quan les peces estan ben protegides, el procés de fabricació de cotxes avança de manera més fluida i ràpida. Hi ha moltes fàbriques que prefereixen les caixes personalitzades de NEXARA simplement perquè mai es deformen, són més duradores i, a més, prou fàcils de netejar ràpidament una vegada i una altra. Això estalvia temps i evita errors. «Quan veus aquestes caixes en acció a fàbriques reals de cotxes, pots veure que no són meres contenidors, sinó eines importants que permeten fabricar cotxes millor i més ràpidament.»

Per què les caixes de plàstic personalitzades per a la logística són clau per a l'eficiència de la indústria automotriu

L'eficiència consisteix a treballar ràpidament sense perdre temps ni materials. Les plantes automobilístiques funcionen seguint un horari estricte perquè moltes peces diferents han de encaixar exactament. La promoció pot facilitar-se mitjançant caixes logístiques de plàstic personalitzades. Com que cada peça d’automòbil és única, les caixes que s’adapten a cadascuna no deixen cap espai sobrant. Per exemple, els cargols petits no ballaran dins d’una caixa gran i les grans peces del motor no quedaran esclafades per una caixa petita. A NEXARA, desenvolupem caixes que ajusten perfectament les peces perquè els treballadors no malgastin el temps netejant o buscant peces perdudes. A més, aquestes caixes es poden apilar i encaixen bé tant a les prestatgeries com als camions de transport, estalviant espai i accelerant el procés de moviment de peces. Un altre factor és que les caixes personalitzades poden tenir etiquetes o codis de colors. Això facilita que els treballadors trobin les peces ràpidament sense haver d’obrir totes les caixes. Quan tot està organitzat, disminueixen els errors i el treball s’accelera. Inclusivé, una caixa pot estar fabricada amb un plàstic especial resistent a l’oli o a la calor, cosa habitual en fàbriques d’automòbils. Això vol dir que les caixes duren més i protegeixen millor les peces. Segons la meva experiència a NEXARA, les empreses que passen a utilitzar caixes personalitzades tindran menys retards i treballadors més contents, ja que la feina serà menys estressant. Al llarg del temps, caixes de plàstic personalitzades per a la logística són molt importants per garantir que tot el procés de construcció de vehicles sigui fluid i ràpid.

Quin és el benefici econòmic de les caixes de plàstic personalitzades al por major per a la indústria automotriu

Per a les companyies automobilístiques, comprar caixes de logística de plàstic personalitzades en massa pot estalviar una quantitat important de diners. Quan NEXARA ajuda una fàbrica, ens assegurem que rebin exactament les caixes que volen, però en grans quantitats. Això fa que el preu per caixa sigui molt més baix que si n’adquireixes només unes quantes. Bàsicament, és com comprar caramels en gros en lloc de per unitat: és més barat des del principi. A més, les caixes personalitzades duren més que les de cartró o les de plàstic econòmic. No es trenquen ni s’acaben ràpidament, de manera que les empreses no han de comprar noves caixes sovint. Això suposa un estalvi de diners al llarg del temps. Un altre factor d’estalvi és la seva contribució a la reducció de residus amb les caixes de NEXARA. No es tracta només que hi hagi menys peces malmeses o perdudes quan s’embalen correctament. Això es tradueix en diners que no caldrà gastar en substituir peces trencades o corregir problemes de muntatge. De tant en tant, les fàbriques tendeixen a pensar que les caixes personalitzades poden semblar cares al principi, però quan es considera el panorama general, són capaces d’estalviar diners, ja que ajuden a fer que el treball sigui més ràpid i les peces més segures. Una altra consideració important és que les bones caixes es poden utilitzar moltes vegades, fins i tot durant anys, a diferència de les caixes de ús únic. Tot això redueix els residus i la necessitat de comprar caixes cada cop. A més, apilar les caixes personalitzades ocupa menys espai als magatzems i als camions, cosa que pot reduir els costos d’emmagatzematge i transport. En la meva opinió, pel que he observat, NEXARA és una inversió intel·ligent quan es compren caixes de plàstic personalitzades en grossa. No es tracta només de comprar un recipient; es tracta d’estalviar i del èxit de tota la cadena d’aprovisionament.

Per què prefereixen els fabricants de cotxes Personalitzat Caixes logístiques de plàstic en lloc de cistelles normals?

Transportar peces i subministraments en la indústria automobilística és essencial per a la seguretat. Les empreses que fabriquen cotxes i camions necessiten controlar moltes peces petites i també grans mentre es traslladen d’un lloc a un altre. Per això, moltes empreses automobilístiques prefereixen caixes logístiques de plàstic personalitzades en lloc de contenidors d’ús general. Aquestes caixes estan dissenyades a mida de les dimensions i forma de les peces que han de contenir. Això vol dir que no hi ha desplaçaments ni danys a les peces durant el transport. Els contenidors convencionals poden ser una mica massa grans o massa petits, i es malgasta espai o es trenca l’equipament. Amb les caixes personalitzades, tot encaixa perfectament, i això es tradueix en estalvis: menys espai malgastat i menys danys.

Els fabricants d'automòbils també prefereixen caixes de plàstic personalitzades perquè són duradores i tenen una llarga vida útil. El plàstic és resistent i pot ajudar a protegir altres peces de la brutícia, l'aigua i el pols. No es corroeix ni es degrada fàcilment. Això és especialment crucial en la logística automobilística, ja que les peces han de mantenir-se lliures de pols i segures fins que s'utilitzen. Potser també pugueu personalitzar les caixes de plàstic o obtenir-ne amb característiques especials o tapadores que encaixin fermament, o nanses integrades per facilitar el transport. Aquests petits detalls ajuden els treballadors a entregar les peces més ràpidament i amb menys riscos. A NEXARA fabriquem caixes logístiques de plàstic personalitzades que compleixen tots aquests requisits. Les nostres caixes permeten mantenir les vostres peces d'automòbil segures i organitzades des del punt A al punt B, accelerant així tot el flux de treball per a vosaltres o els vostres clients.

Les caixes personalitzades també ajuden les companyies automobilístiques a ser més respectuoses amb la natura. Com que aquestes caixes tenen una llarga vida útil i es poden reutilitzar nombroses vegades, les empreses no malgasten contenidors després d’un sol ús. Això no només redueix els residus, sinó que també estalvia recursos. Un material exclusiu, d’alta qualitat i 100 % reciclat és una de les característiques més destacades de NEXARA’s caixa logística de plàstic . És a dir: els fabricants d’automòbils poden ser respectuosos amb el medi ambient i amb les seves peces. En conclusió, per al sector automobilístic és millor reutilitzar caixes logístiques de plàstic personalitzades per mantenir les peces a salvo de danys, estalviar uns quants diners, fer les tasques més gestionables i protegir el planeta.

Per què utilitzar logística automotriu amb caixes de plàstic personalitzades per a problemes habituals?

Hi ha un nombre important de problemes en la logística automotriu, com el moviment de peces des d'instal·lacions fabrils fins a les línies de muntatge o botigues. Un d'aquests problemes és que les peces poden perdre's, danysar-se o embrutar-se durant el transport. Molts components automotrius senzillament no s'adapten bé als contenidors estàndard. Una caixa plàstica personalitzada per a la logística soluciona aquests problemes, ja que està dissenyada específicament per contenir les peces transportades. Quan les peces encaixen bé i de manera ajustada dins les seves caixes, no es desllizen ni xoquen entre si. Això minimitza el risc de danys o robatoris. Les nostres caixes personalitzades a NEXARA estan adaptades a la mida i forma ideals, assegurant que fins i tot les peces més fràgils arribin sans i salves al seu nou destí.

Un altre problema dins la logística automotriu és la utilització de l'espai. Els camions i els magatzems tenen limitacions d'espai, per tant és important empaquetar bé per optimitzar el nombre de peces per càrrega de contenidor. Els contenidors estàndard poden ser massa grans o tenir formes estranyes, ocupant més espai i costant més diners. Les caixes de plàstic personalitzades de NEXARA poden ajudar a resoldre aquest problema, ja que es poden apilar de manera ordenada i compacta. Aquesta és una manera d'estalviar espai per transportar o emmagatzemar més peces en el mateix àrea. Una utilització més eficient de l'espai equival a uns costos de transport més baixos i un treball més ràpid.

Mantenir les peces netes i seques també és difícil. Quan no s'utilitzen, les peces automotrius aliades s'han de mantenir lliures de brutícia, pols i humitat. Les caixes logístiques de plàstic estan dissenyades per mantenir les peces seques i netes. Poden tenir tapes ajustades o altres segells especials per evitar l'entrada de pols i aigua. Això és extremadament valuós quan es transporten components llargues distàncies o es desen durant períodes prolongats de temps. Les caixes universals de NEXARA estan dissenyades per protegir qualsevol tipus de peça dels elements.

Finalment, pot ser un repte controlar i organitzar nombroses peces. Les empreses automotrius gestionen una gran varietat de peces i eines, i no és estrany que algunes coses s'extraviïn o es perden. Les caixes logístiques de plàstic personalitzades poden portar etiquetes, colors o codis per ajudar els treballadors a saber què contenen. Això permet classificar i localitzar les peces més ràpidament. NEXARA disposa de solucions adaptades amb aquestes característiques útils per garantir una logística automotriu eficient i fiable.

On demanar caixes personalitzades de logística de plàstic de la millor qualitat per a comandes automotrius massives

Tanmateix, quan una empresa automobilística necessita grans quantitats de caixes de logística de plàstic a mida, és essencial treballar amb algú que pugui subministrar un producte d’alta qualitat a temps i a un bon preu. Demaneu a l'empresa adequada i les caixes seran resistents, segures i dissenyades personalment per adaptar-se a les peces que hauran de contenir. NEXARA és el destinatari idoni per comprar caixes de logística de plàstic personalitzades per a compres massives automotrius. Coneixem bé el sector automobilístic, i col·laborem tant entre nosaltres com amb els fabricants per dissenyar caixes resistents que ofereixin solucions a problemes.

Utilitzem materials d'alta qualitat per fabricar les nostres caixes personalitzades. Això fa que les caixes siguin prou resistents per suportar càrregues més pesades i un maneig dur sense trencar-se. I amb les nostres mides i dissenys, poden tenir exactament el que desitgen per a la seva empresa automotriu. NEXARA pot fabricar ràpidament qualsevol quantitat de caixes, grans o petites, i oferir una lliurament puntual. Això assegura el funcionament fluid de les línies de muntatge de cotxes sense interrupcions.

Una segona raó per comprar a NEXARA és el nostre compromís amb el servei. Assistem els fabricants d'automòbils per desenvolupar i provar la seva caixa personalitzada abans de realitzar comandes grans. Això assegura que les caixes encaixin perfectament amb les peces tal com estan dissenyades i funcionin bé en l'ús logístic sota condicions reals. També oferim orientació sobre com utilitzar millor les caixes per augmentar la productivitat i estalviar costos. Per a les empreses que volen reforçar les seves cadenes d'aprovisionament, aquest suport pot ser molt beneficiós.

Això és perquè NEXARA també té present l'entorn. El nostre plàstic palet de logística les caixes són reutilitzables i reciclables, assegurant beneficis econòmics per a vostè. En utilitzar les caixes de NEXARA, les corporacions automotrius podran reduir els residus i disminuir la seva petjada ecològica. Això és especialment important per a les empreses que desitgen ser responsables i verdes.

En resum, si és un comprador del sector automotriu i desitja adquirir la personalització logística de caixes de plàstic, NEXARA és una elecció encertada. Disposem de caixes d'alta qualitat i duradores que pot demanar, així com d’un excel·lent suport al client tot passant a ser més ecològic! Col·laborar amb NEXARA permet als fabricants automotrius protegir les seves peces, estalviar diners i operar de manera més eficient dia rere dia.

El contingut

- Per què les caixes de plàstic personalitzades per a la logística són clau per a l'eficiència de la indústria automotriu

- Quin és el benefici econòmic de les caixes de plàstic personalitzades al por major per a la indústria automotriu

- Per què prefereixen els fabricants de cotxes Personalitzat Caixes logístiques de plàstic en lloc de cistelles normals?

- Per què utilitzar logística automotriu amb caixes de plàstic personalitzades per a problemes habituals?

- On demanar caixes personalitzades de logística de plàstic de la millor qualitat per a comandes automotrius massives

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

GA

GA

CY

CY

BE

BE

BN

BN

/images/share.png)