In the production of small parts organization and security are very important. That’s where plastic logistics boxes come into play. Now, these boxes are not just any box, by no means; there special varieties designed to assist manufacturers store, transport and handle small items that include screws, bolts and other tiny parts. NEXARA provides the boxes, which can drive significant operational changes for manufacturers. The companies can save time, cut down on waste, and enhance their overall efficiency using the right logistics boxes. Here’s why you need these boxes and how to make the best pick for your needs.

The main advantages of Plastic Logistics Boxes In Manufacturing - What are the major advantages of using Plastic in Manufacturing?

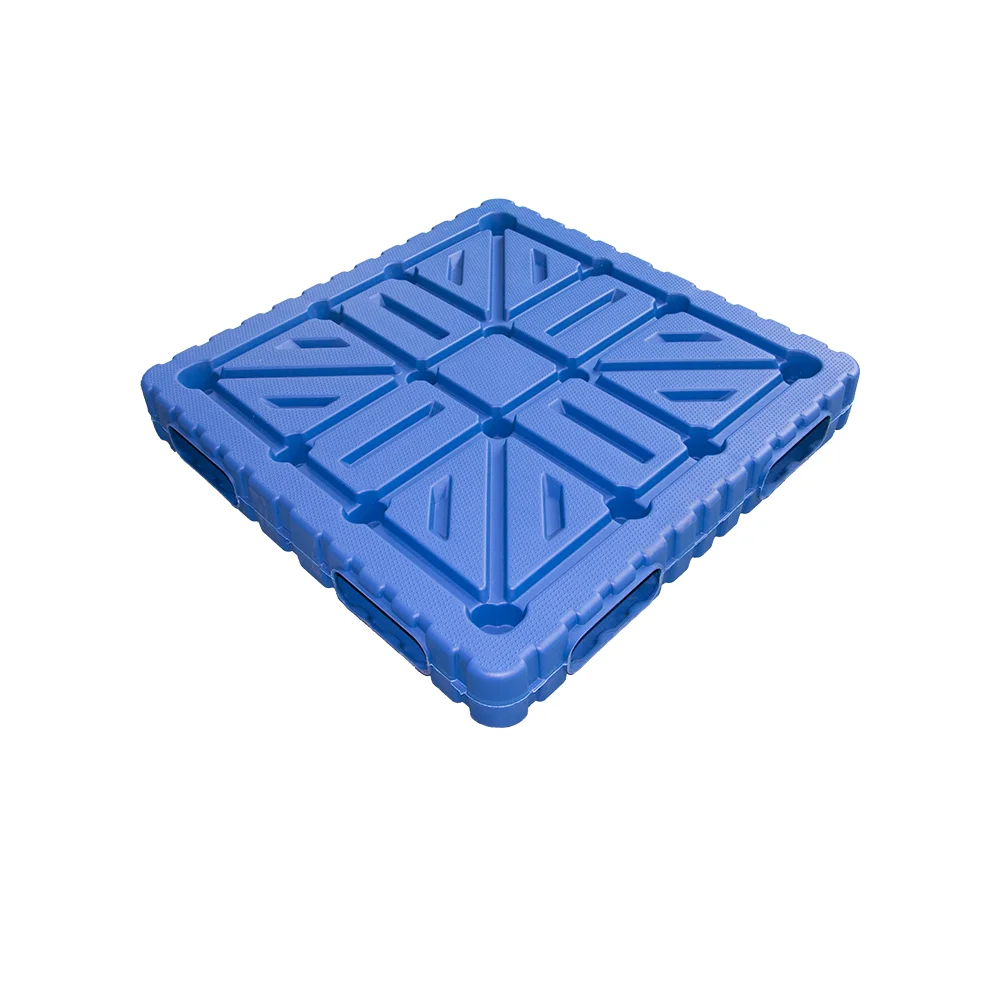

There are many advantages to using plastic in small parts manufacturing. One, the boxes are strong and can protect whatever inside. Your delicate small parts, for instance, would be kept from being crushed during transport when they are kept in a tough plastic box. This can prevent problems like the need to replace parts, which can be costly and inconvenient. They are also very light, another bonus. That means they can be moved with ease by workers, who won’t tire out as quickly. If you think about a busy factory, people are always moving stuff.” Lighter boxes means an easier and faster job.

What’s more plastic logistics crates are really versatile. They’re manufactured in various sizes and shapes, meaning there’s a perfect fit for any kind of little part. That flexibility keeps everything organized. For instance, suppose you have various types of screws to keep separated. You can also use different boxes to avoid mixing them up. This is an organization that makes it possible for you to find what you want easily. NEXARA’s boxes also usually come with lids, which keep the dust and grime away. This is significant because the cleaner the parts are, the better they’ll work in the machines for which they are fabricated.

Finally, the boxes themselves are so easy to clean and can be used over and over again. Unlike cardboard boxes, which wear out and have to be replaced, plastic boxes can last for years. And most of the time, they can look new with just a quick wipe down. Not only does it save money, but it’s better for the planet: Waste is saved. All in all, you can see that plastic logistics boxes just make sense for small parts manufacturing.

How to Select the Applicable Plastic Turnover Box for Small Part Storage?

The right choice of a plastic logistic box can sound difficult at times, but it doesn’t have to be. First, start by thinking about the size of the pieces you need to store. If you have little components, a smaller box is best. But if the pieces are bigger, you’ll want a bigger box. NEXARA offers varied sizes thus you can choose the best size for your needs. The weight of whatever is inside it makes another great impact. If the parts are heavy, be sure to choose a box made of thicker plastic that can support the weight without cracking.

Next up: how will you use the boxes? Will they be stacked? If you do, then select the boxes that are meant to stack up. This saves space in your factory. Some boxes are even specially designed to fit together seamlessly when stacked, in order to make sure you can use every inch of your storage location. And consider whether you need lids. Having lid can protect parts from falling out or dirty at work place; so good to use in the office, house, lab and DIY studio.

You should also consider how frequently the boxes will get a cleaning. If you like them to be very tidy at all times, opt for a box thats easy to wash. Some plastic containers can even go in the dishwasher, for easy cleaning. Finally, the cost itself is nothing to sneeze at. Quality vs. cost: There’s a balance to be struck here. NEXARA comes in a variety of prices, so you’re bound to find boxes that match your budget without limiting quality. By taking them into account, you will be able to make the best decision for your small parts holding.

Plastic Logistics Boxes - Common Usage Problems and Prevention

Plastic boxes for logistics during manufacturing plastics logistic containers are ideal to keep small parts safe and in order. But there are some typical troubles people run into when using them. The size of the box for the parts is a issue. If the box is too large, the parts can shift around and be damaged. If the app are small, then the parts might not fit for you and cause stress and frustration. To prevent this, you should measure the parts and choose a box that will comfortably house them. Another issue is that of overloaded boxes. It can be heavy to move if one box has too much in it. This may result in the box breaking open or parts falling out. Always abide by the weight limit listed on the box and simply never exceed a safe level to avoid this.

Also, plastic boxes may become dirty or soiled. If the box is not cleaned thoroughly, you can get contamination and that’s not what we want for manufacturing. Keeping the boxes clean and inspecting them for cracks or breaks may help keep everyone safe. Finally, leaving all of the parts in the boxes can make things complicated. It takes far longer to locate what you need when parts are all mixed up, and the same applies to make tic-tact-toe-worthy progress. To avoid this, highly label the boxes and keep similar pieces together. And by employing these tips we can ensure plastic logistics boxes are used correctly keeping issues at bay and making jobs as easy as possible.

Why are Plastic Logistics Boxes good for Efficient Operations?

Plastic Logistics Box is indispensable for the streamlined operations of small parts manufacturing. They're hugely important for the very simple reason that they help you keep everything neat and tidy. It’s simple to know what you’ve got inside while parts are stored in plastic containers. It saves time when employees have to go look for things. Rather than rummage through a heap of parts, they can just pick up the right box. Even its critics concede this makes the whole operation a bit easier to run.

Another important advantage is that they are durable being plastic logistics boxes. They are tough enough to not damage easily when handled roughly and they protect the smaller parts inside. Less to break and less waste is better for business. Moreover, these boxes weigh less that allow you to carry and transport easily. It is also very convenient on an assembly line when workers must move parts rapidly.

Plastic logistics crates are stack as well. This has the effect of being able to be stacked upon one another without taking up too much space. When you are in a small production space, space is limited and being able to stack boxes helps maintain order as well as makes the most of your rooms capabilities. And many plastic boxes are reusable. It's a money saver plus it's good for the environment, because our planet consumes less waste. Small parts manufacturers can greatly benefit from more organized, efficient and greener workspace by using plastic logistics boxes.

Where to Get High-Quality Logistic Boxes for Small Parts Production Made of Plastic

Reliable source molded plastic logistics boxes for small parts manufacturing Looking for the best source of plastic logistics boxes for small parts production? One great way to do this is by searching for best-in-class storage solutions providers such as NEXARA. Plastic boxes NEXARA Provides an extensive range of plastic logistics box in multiple sizes and styles. This also means that you can discover the ideal box based on your preference. If you need a small box for micro parts or a larger one for some bigger gear, NEXARA has something that will work out suited to your needs.

The internet can also be a great place to find plastic logistics boxes. Lots of websites sell storage solutions and you can usually read customer reviews to help decide which boxes are the best. Do not forget that the material and sturdy construction of the boxes will reflect how your parts will be protected. It is also a good idea to search for companies that have features like bulk ordering. Purchasing in bulk will save you with the money and have enough boxes available for all of your manufacturing needs.

Seeing those boxes in person at a local store can help ensure they meet your needs and then some. You can also get tips from the staff on which products will be best for your business. Finally, be mindful of the product return policy when you are buying boxes. If they are not suitable for you, it’s a bonus if you can return them for a refund. Small parts manufacturing You can run your small parts manufacturing plant efficiently by purchasing quality plastic logistics boxes lineup from reliable sources like NEXARA.

Table of Contents

- The main advantages of Plastic Logistics Boxes In Manufacturing - What are the major advantages of using Plastic in Manufacturing?

- How to Select the Applicable Plastic Turnover Box for Small Part Storage?

- Plastic Logistics Boxes - Common Usage Problems and Prevention

- Why are Plastic Logistics Boxes good for Efficient Operations?

- Where to Get High-Quality Logistic Boxes for Small Parts Production Made of Plastic

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

GA

GA

CY

CY

BE

BE

BN

BN

/images/share.png)