You have seen wooden frames which are used to lift bulky items right? What here is called a "pallet"- these wooden frames. Pallets: This is really big because they help to move food, toys, clothes and many other types of products from one place to another. They aid workers in picking up and carrying heavy loads at work. But did u know there is a faster better way to get pallet done. This new process is aptly named “pallet injection molding,” and it may serve as a revolution in the world of pallet manufacturing!

In addition, the charge of pallet injection molding is lower than ordinary. The used plastic materials are also recyclable and resuable so the use of it cost less than normal wooden pallets. Wonderful news for any business wanting to save money! Secondly, since the plastic is also a lightweight material it make pallet lighter than wooden ones. The lower weight will then save even more money during shipment when carrying goods.

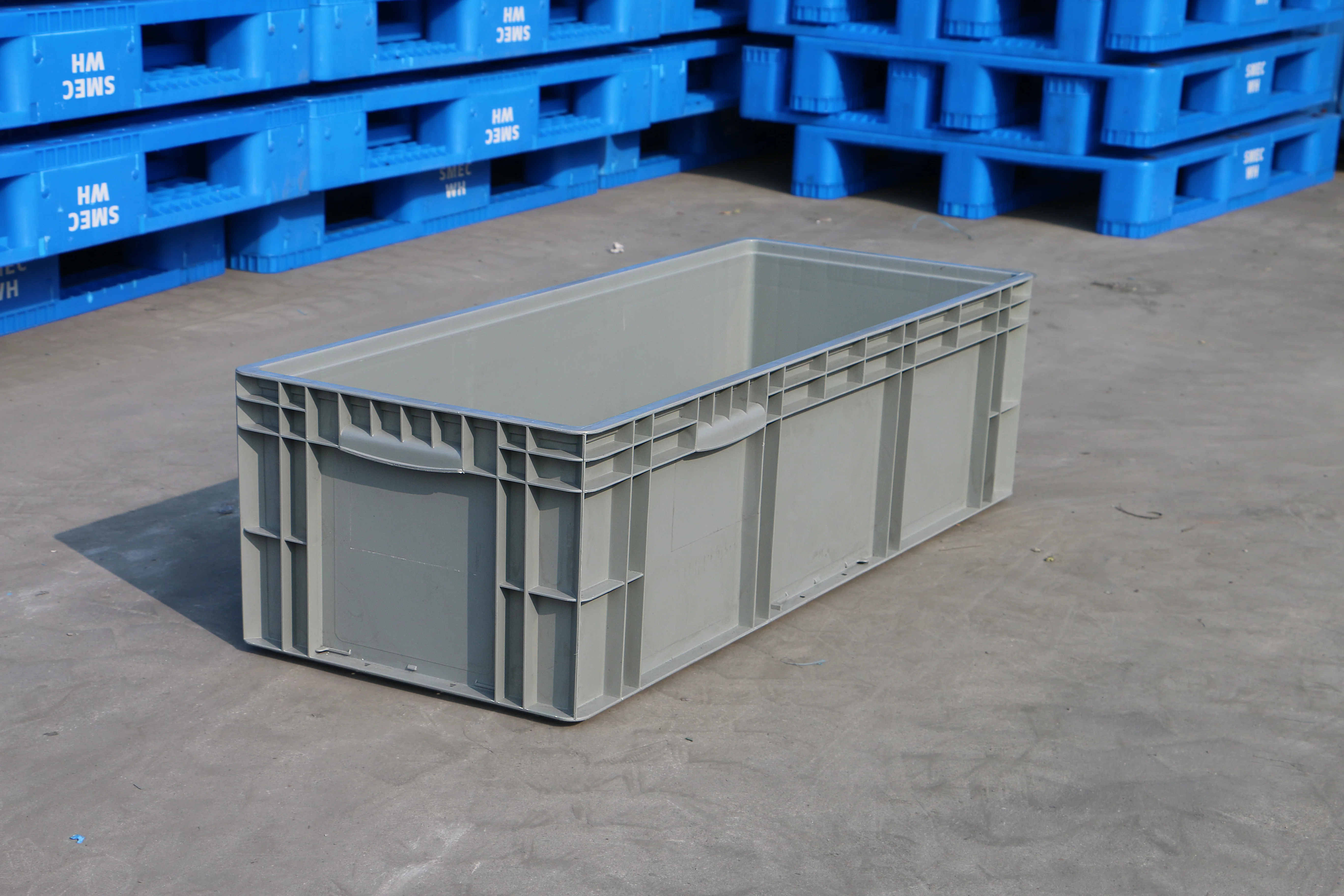

In Packaging, The main thing is Pallets used in most of Warehouses and Shipping companies. They help to prevent items from getting damaged in transit, and make it easier for you to lift heavy objects off the floor. But, Common Wooden Pallets have a few of the issues. They are heavy and difficult to maneuver, not to mention they can break so easily. Which is why pallet injection molding comes in SUPER handy!

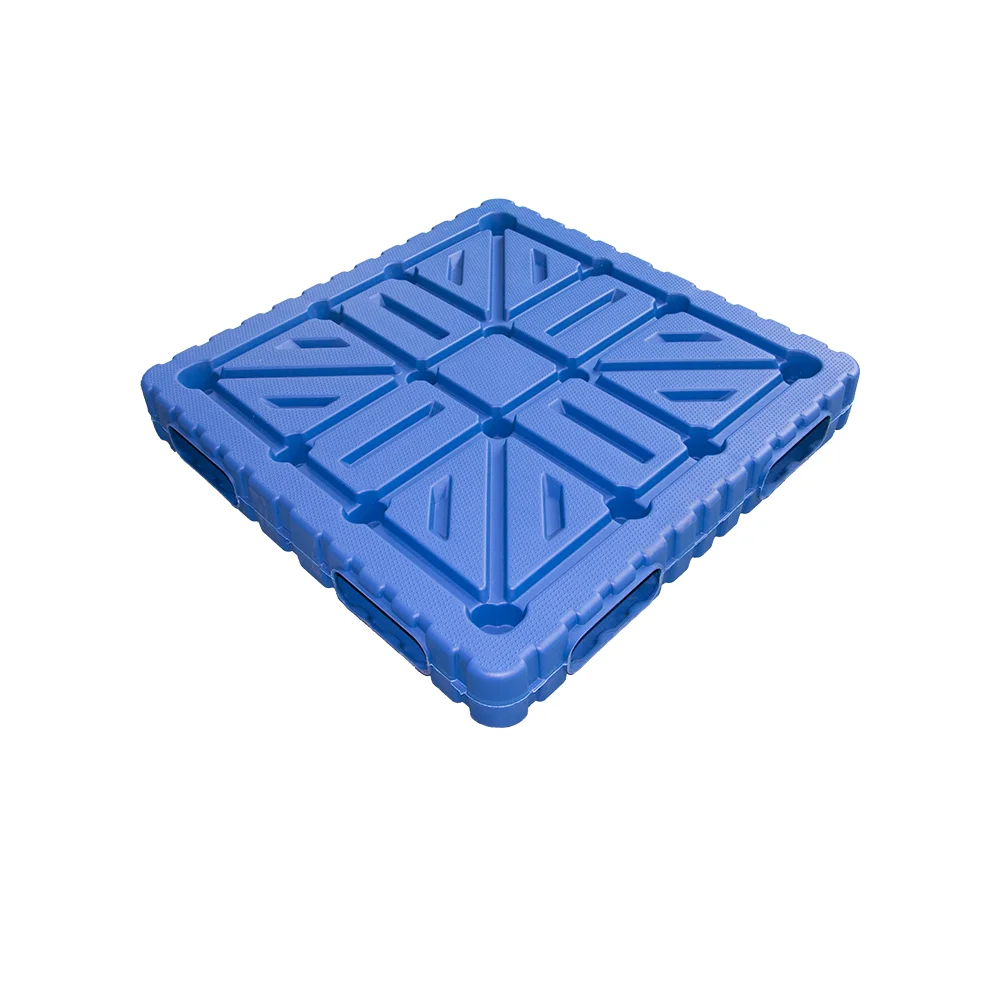

Pallet can be in many shapes and sizes with pallet injection molding. Ideally, it is quite suitable for wide range of products For example, some pallets are made with wheels builtin so that they can be effortlessly moved like the products are pushed on them without physical force. There are regular pallets which have holes in them so that air can pass through and those are good for food products because you want the fresh foods to breathe. There are endless opportunities of these types of pallets products!

Pallet injection molding is very efficient; that's one of the advantages it has over other methods. Since many of these pallets are made from the same mould, it enables multiple to be produced quickly and at an exact size shape Businesses that need to stack and store pallets neatly depend on this consistency. Furthermore, plastic pallets do not splinter or break like wooden ones, thus reducing money and time costs from having to replace them. In addition, plastic pallets are far lighter than wood so it is easier for workers to lift and carry as they pack product or move shipments.

Time, and money saved When businesses Use Plastic Pallets in Place Of The Traditional Wooden Ones Plastic - Plastic pallets can be manufactured quickly and typically will not break or need to be replaced, reducing downtime for businesses. Because the plastic pallets are so lightweight, companies may be allowed to ship more products at once due to reduced shipping costs! Pallet injection molding can help your business to simplify and streamline its supply chain, which is vital if you want it run smoothly.

Recyclable: Plastic pallets can be recycled for a unlimited number of times, meaning there use is less harsh on the environment when compared to traditional wooden pallets. Recyclables made from plastics recycle waste and make our planet sustainable. Also, plastic pallets are relatively light weight which can assist in reducing pollution as it relates to transportation. Pallet injection molding will take a larger and larger share in industrial packaging sector when more businesses are seeking eco-friendly solutions.

We the opportunity offer customers most affordable product. We constantly pushing limits technological innovation within industry. Our RD team not just a position design pallet injection technologies meet needs customers however, they also have flexibility customize moulds modify materials suit customer specifications. This degree customization keeps us ahead market guarantees highest value our customers.

With operations spread across globe, team pallet injection international outlook rich cross-cultural experience, we able understand satisfy requirements customers diverse areas backgrounds, providing tailored solutions.

We're determined achieve pallet injection economic benefits environmental protection. products services comply principles sustainable development which not only clients increase efficiency productivity but while minimizing impact environment.

clients the greatest assets us. team customer service professionals always hand pallet injection timely thoughtful assistance, ensures most pleasant customer experience during journey through products services.